Introduction to Diesel Pumps

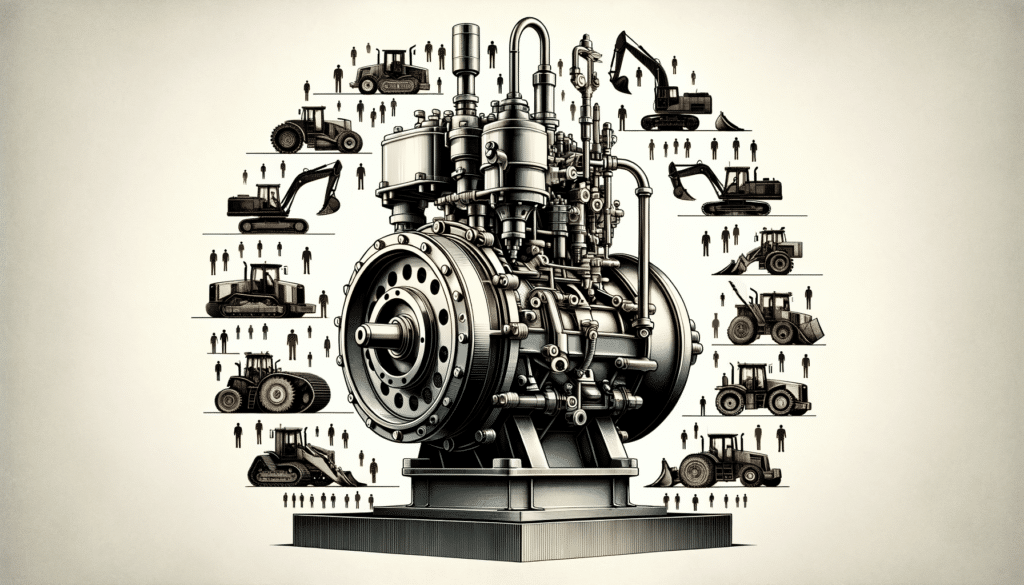

Diesel pumps play a pivotal role in numerous industries, serving as the backbone for heavy machinery and vehicles that rely on diesel fuel for their operation. These pumps are designed to handle the robust demands of industrial environments, ensuring that diesel fuel is delivered efficiently and reliably. Understanding the intricacies of diesel pumps is essential for anyone involved in industries such as construction, agriculture, or logistics, where the performance of machinery can directly impact productivity and profitability.

Types of Diesel Pumps

Diesel pumps come in various types, each designed for specific applications and performance requirements. The two primary categories are mechanical and electronic diesel pumps. Mechanical diesel pumps are traditional, relying on a series of gears and levers to move fuel from the tank to the engine. They are known for their durability and simplicity, making them a popular choice in older machinery and vehicles. On the other hand, electronic diesel pumps utilize advanced technology to control fuel delivery with precision. These pumps offer enhanced efficiency and are often found in modern diesel engines.

Key differences between mechanical and electronic diesel pumps include:

- Precision: Electronic pumps provide more accurate fuel delivery.

- Maintenance: Mechanical pumps are easier to repair and maintain.

- Efficiency: Electronic pumps are generally more fuel-efficient.

Applications of Diesel Pumps

Diesel pumps are integral to a wide range of applications, from powering construction equipment to fueling agricultural machinery. In the construction industry, diesel pumps are used in excavators, bulldozers, and cranes, where they must deliver consistent power under demanding conditions. In agriculture, these pumps are essential for tractors and harvesters, ensuring that they operate smoothly during critical planting and harvesting seasons. Additionally, diesel pumps are found in logistics and transportation, where they fuel trucks and buses, contributing to the seamless movement of goods and people.

Benefits of Using Diesel Pumps

The use of diesel pumps offers several advantages, particularly in settings where reliability and efficiency are paramount. Diesel fuel is known for its energy density, which provides more power per unit than gasoline. This makes diesel pumps an excellent choice for heavy-duty applications. Furthermore, diesel engines tend to have a longer lifespan, reducing the need for frequent replacements and repairs. Diesel pumps also contribute to lower operational costs, as diesel fuel is often more economical than other fuel types.

- Energy Efficiency: Diesel pumps offer superior energy efficiency compared to gasoline pumps.

- Longevity: Diesel engines and pumps are built to last, providing long-term value.

- Cost-Effectiveness: Lower fuel costs and maintenance expenses make diesel pumps a cost-effective option.

Maintenance and Care for Diesel Pumps

Proper maintenance of diesel pumps is crucial to ensure their longevity and optimal performance. Regular inspections and servicing can prevent common issues such as leaks, clogs, and wear and tear. It is important to follow the manufacturer’s guidelines for maintenance, which typically include checking fuel filters, inspecting seals, and ensuring that the pump is free from debris and corrosion. Additionally, using high-quality diesel fuel can help prevent damage and extend the life of the pump.

Maintenance tips for diesel pumps include:

- Regular Inspections: Schedule routine checks to identify potential issues early.

- Fuel Quality: Use clean, high-quality diesel fuel to prevent clogs and damage.

- Professional Servicing: Engage qualified technicians for complex repairs and servicing.

Conclusion

In conclusion, diesel pumps are indispensable components across various industries, providing the necessary power and reliability for heavy machinery and vehicles. Understanding their types, applications, benefits, and maintenance requirements can help businesses maximize their investment in diesel-powered equipment. By ensuring proper care and selecting the right type of pump for specific needs, industries can enhance their operational efficiency and achieve long-term success.